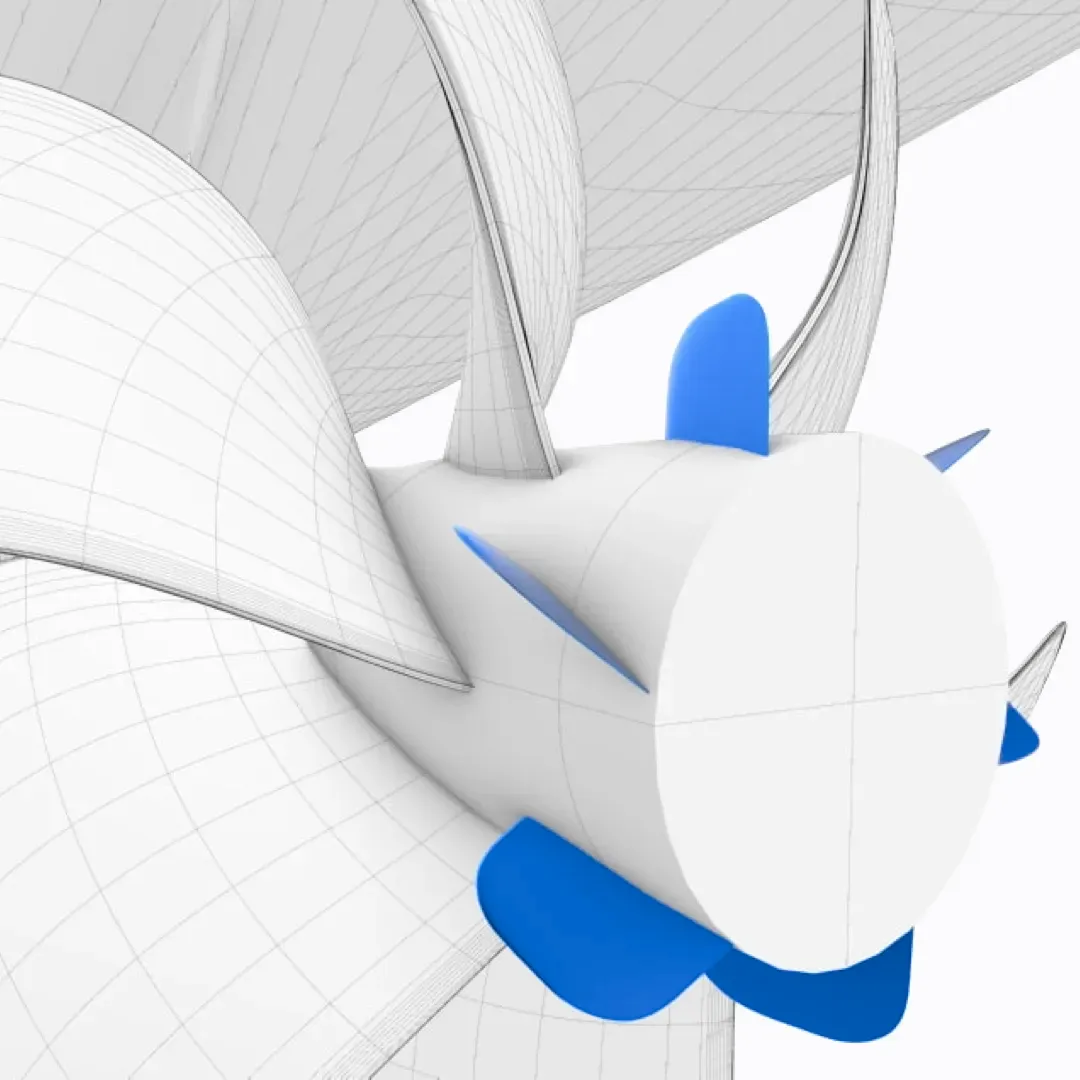

Pre-Swirl Stator (PSS):

Innovative Energy Saving Device

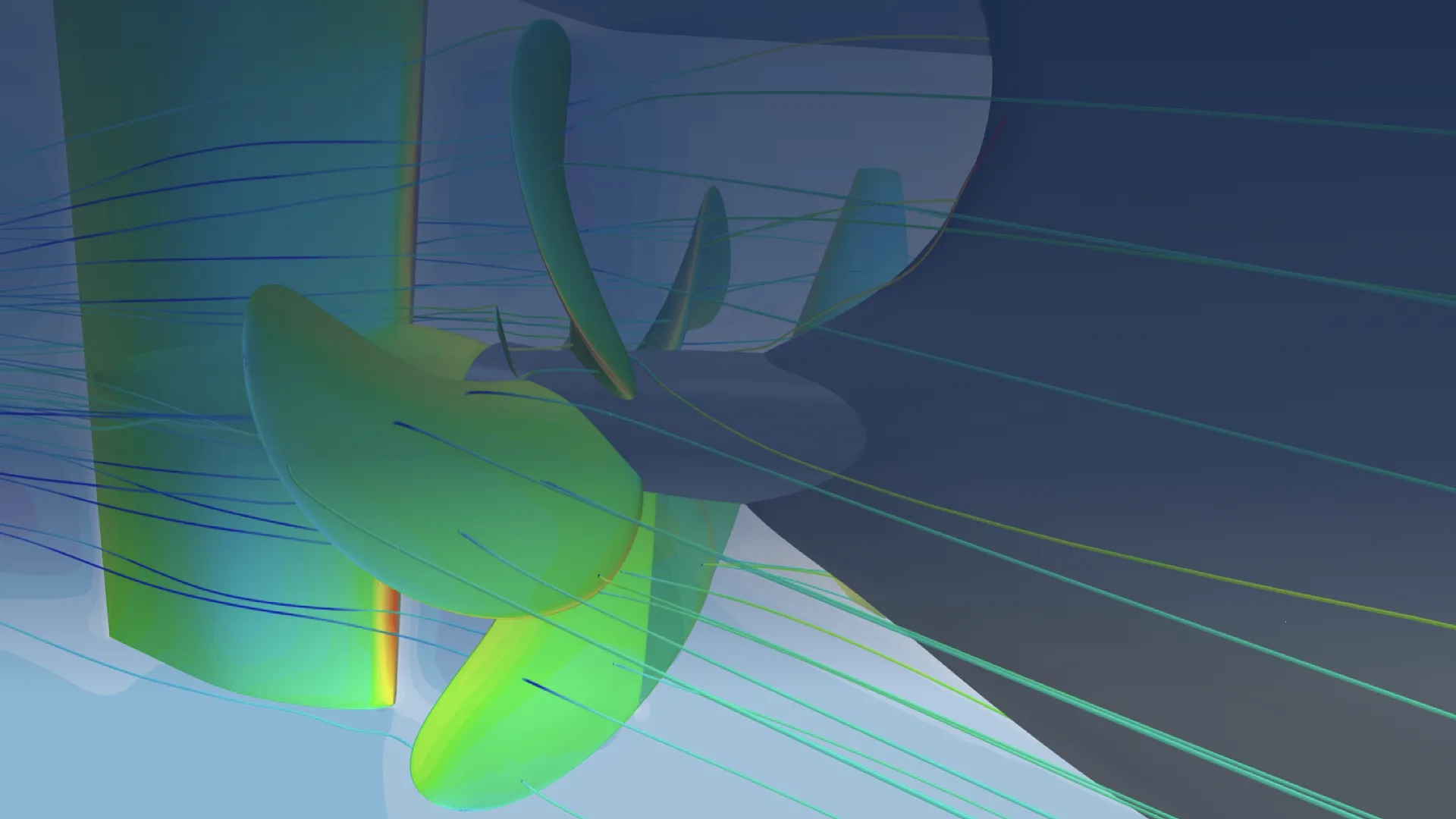

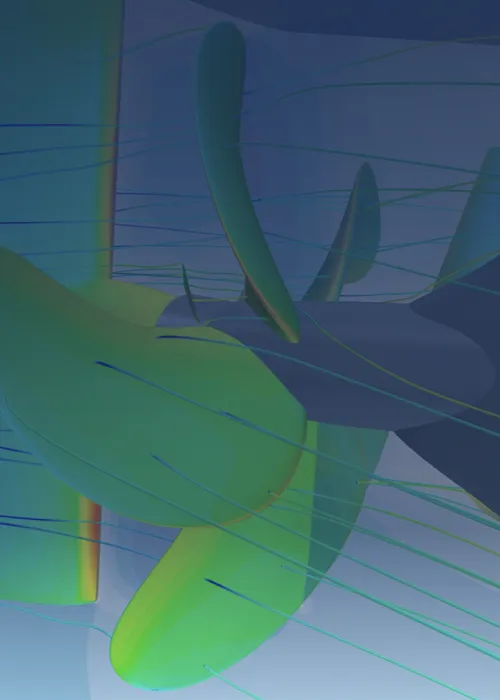

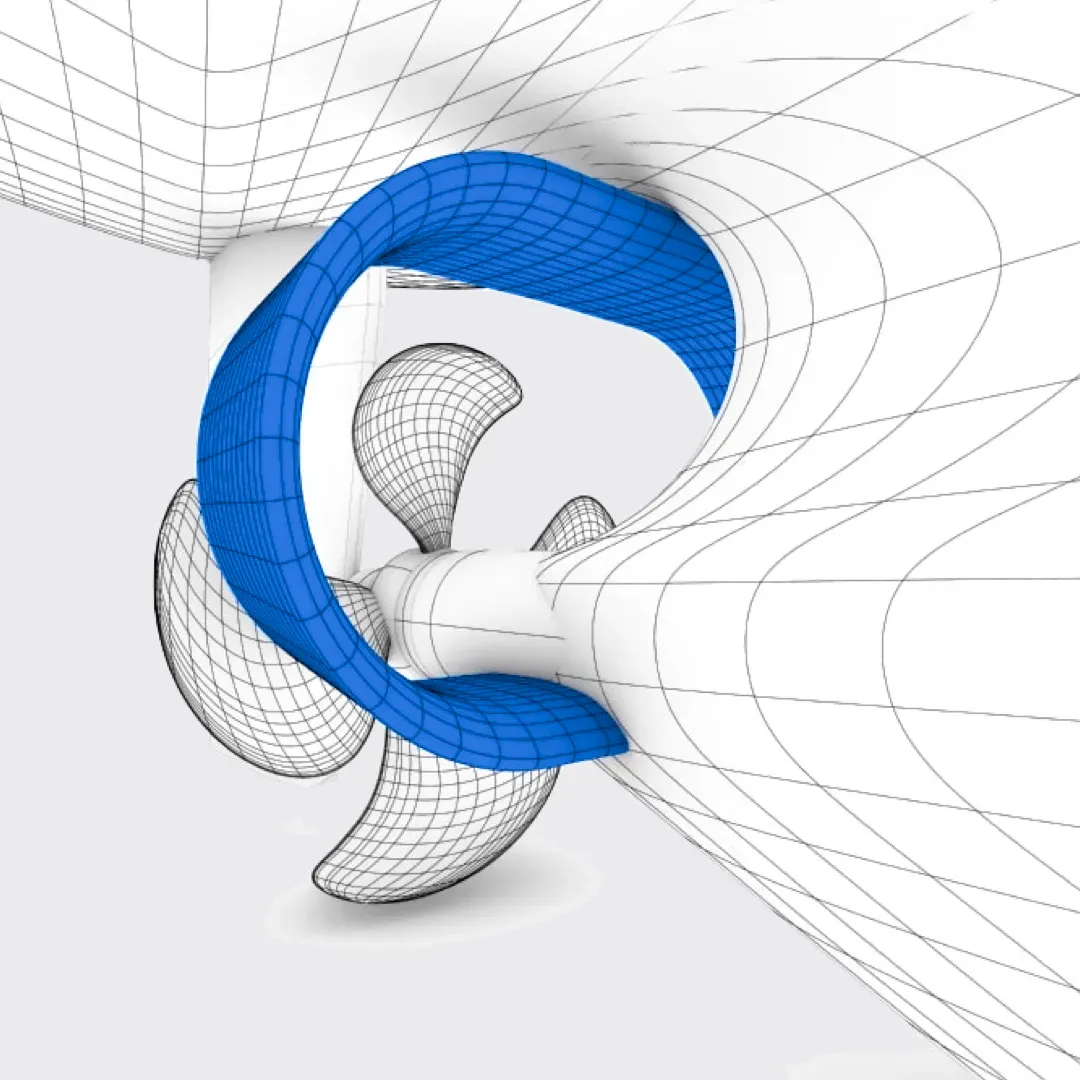

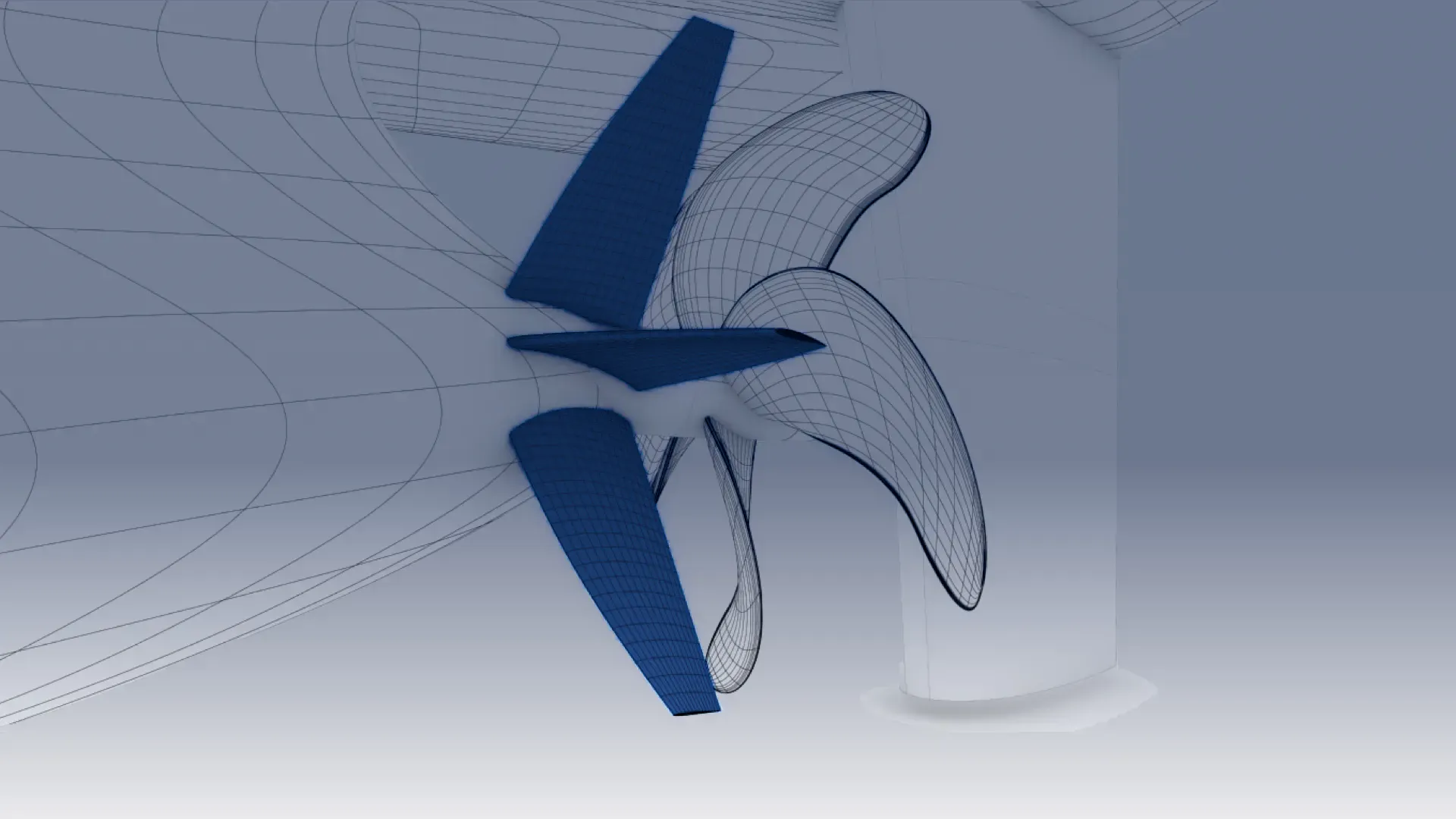

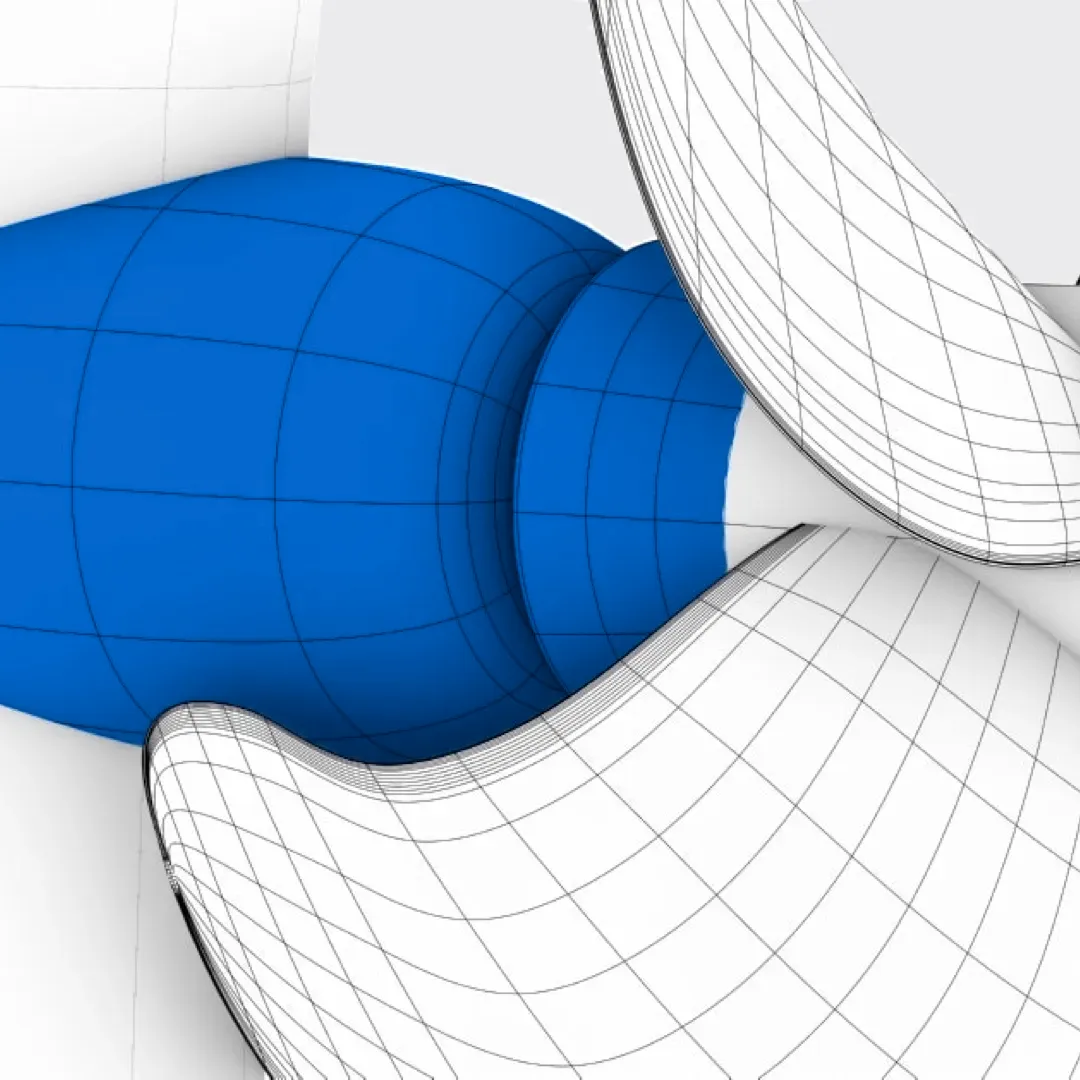

The Pre-Swirl Stator (PSS) is a high-quality Energy Saving Device designed to improve the flow efficiency of ships. Strategically positioned fins create a controlled counterflow in the water before it reaches the propeller, reducing energy losses caused by the swirl of the rotating propeller. This leads to increased thrust per unit of energy consumed, resulting in better performance and lower fuel consumption.

Using scientifically validated numerical flow analyses (CFD), the engineers can accurately determine the optimal position and angle of the fins. Factors such as speed, load, and sea state are taken into account to ensure the system performs optimally under various operational conditions.

The Pre-Swirl Stator can achieve fuel savings of 4 to 8%, directly contributing to a significant reduction in CO2 emissions. This technology, together with other Pre-swirl and Post-swirl devices, supports the environmental objectives of the International Maritime Organization (IMO), such as the Energy Efficiency Design Index (EEDI), the Energy Efficiency Existing Ship Index (EEXI), and the Carbon Intensity Indicator (CII). These initiatives aim to improve the energy performance of ships and reduce the ecological footprint of global shipping.

This type of ESD can be applied to both newbuilds and existing vessels, ensuring lasting efficiency improvements for various ship types, such as dry cargo ships, RoRo vessels, and passenger ships. By continuously contributing to better propulsion performance and reduced environmental impact, this technology supports the transition to more sustainable shipping.