Products for Ship Propulsion

Optimizing the propulsion of your vessel is essential for enhancing its sustainability and energy efficiency. More efficient propulsion systems reduce fuel consumption and emissions, leading to lower operational costs and compliance with environmental regulations such as the Carbon Intensity Indicator (CII). This not only strengthens your competitive position but also ensures the future viability of your shipping business. Discover the products for ship propulsion that are suitable for both your existing fleet and future ship designs.

Ship Propeller

In comparison to a traditional ship propeller, which is typically designed using empirical formulas and experience-based design methods, a CFD-optimized ship propeller integrates practical experience with validation. This not only enhances the efficiency of your vessel but also reduces noise and vibrations, promotes environmental friendliness, and provides accurate performance predictions.

CPP Blades

The reproduction of Controllable Pitch Propeller (CPP) blades can offer various benefits for shipowners and operators. Firstly, reproduced CPP blades can deliver the same performance and functionality as original blades, potentially at lower costs. Additionally, reproducing CPP blades can enable customized improvements, such as design optimization for specific applications, increased efficiency, or enhanced performance under certain conditions.

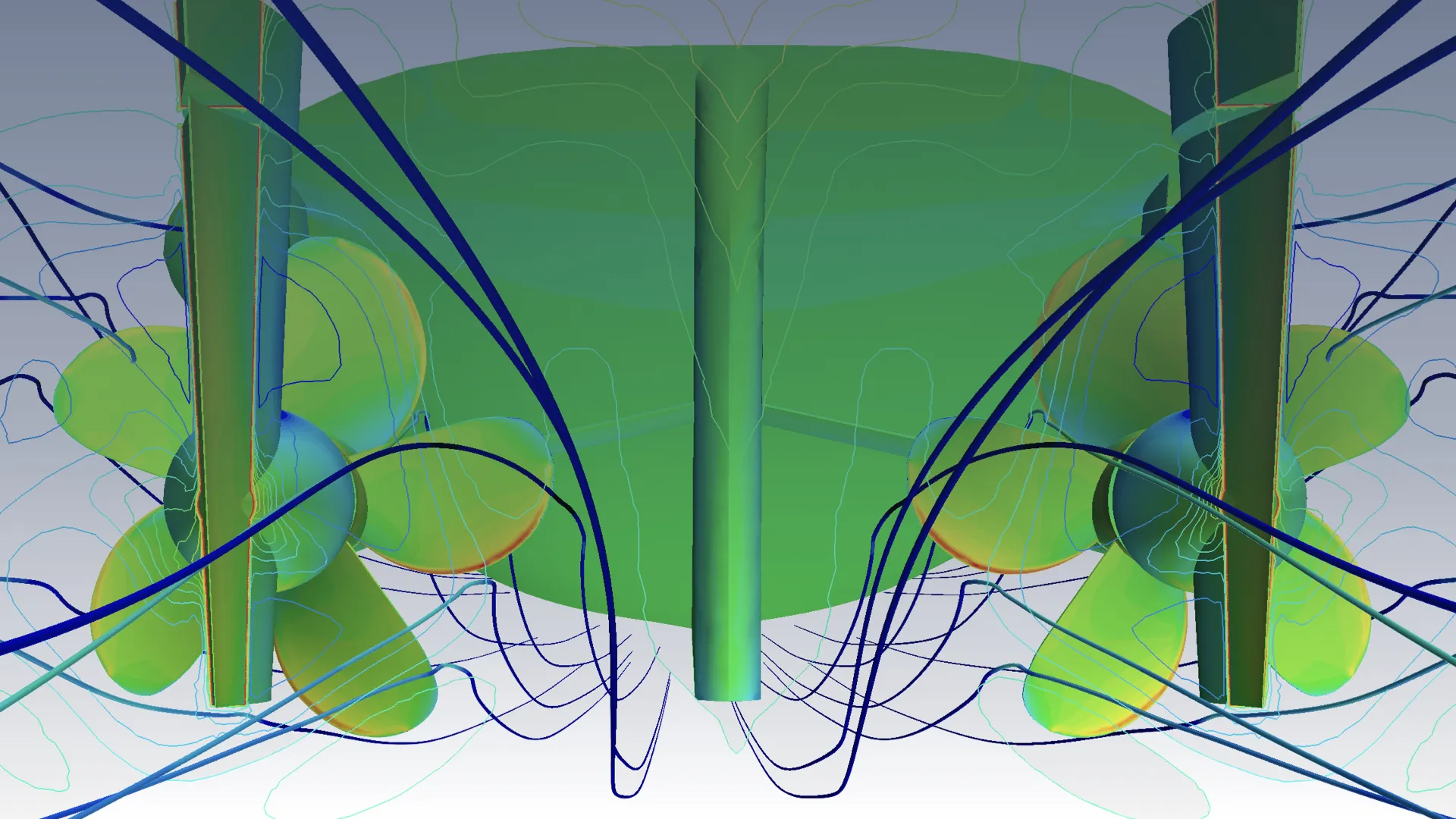

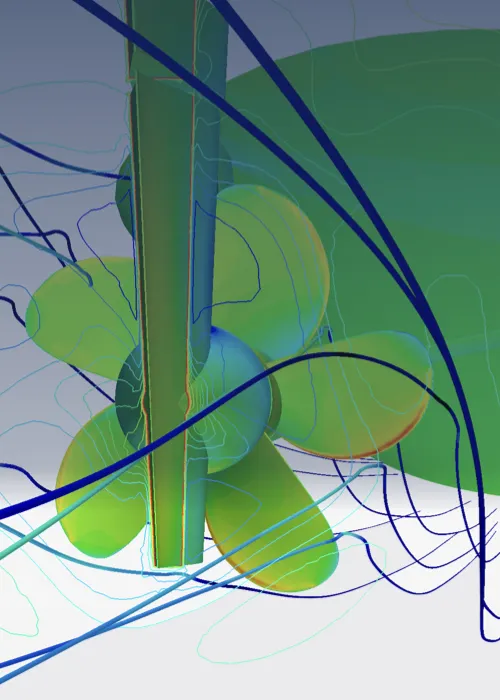

Propeller Nozzle

A propeller nozzle is a cylindrical tube placed around the outside of a ship’s propeller. It acts as a housing for the propeller and directs the water flow generated by the propeller. In a fixed-pitched ducted propeller system, the propeller is placed within the nozzle, concentrating the thrust of the propeller into a focused jet behind the ship. Applying CFD analyses in the design of the propeller and nozzle increases propulsion efficiency, improves maneuverability, and reduces the risk of damage to the propeller and rudder.

Ship Rudder

A CFD-optimized ship rudder offers numerous benefits. These include enhanced maneuverability and safety, increased fuel efficiency due to reduced drag and improved hydrodynamic performance, and the ability to reduce noise and vibrations. This contributes to cost savings, environmental friendliness, and improved onboard comfort, making it essential for more efficient and sustainable sailing.

Products for Ship Propulsion

Discover the products for ship propulsion that are suitable for both your existing fleet and future ship designs.

Ship Propeller

In comparison to a traditional ship propeller, which is typically designed using empirical formulas and experience-based design methods, a CFD-optimized ship propeller integrates practical experience with validation.

This not only enhances the efficiency of your vessel but also reduces noise and vibrations, promotes environmental friendliness, and provides accurate performance predictions.

CPP Blades

The reproduction of Controllable Pitch Propeller (CPP) blades can offer various benefits for shipowners and operators. Firstly, reproduced CPP blades can deliver the same performance and functionality as original blades, potentially at lower costs.

Additionally, reproducing CPP blades can enable customized improvements, such as design optimization for specific applications, increased efficiency, or enhanced performance under certain conditions.

Propeller Nozzle

A propeller nozzle is a cylindrical tube placed around the outside of a ship’s propeller. It acts as a housing for the propeller and directs the water flow generated by the propeller. In a fixed-pitched ducted propeller system, the propeller is placed within the nozzle, concentrating the thrust of the propeller into a focused jet behind the ship.

Applying CFD analyses in the design of the propeller and nozzle increases propulsion efficiency, improves maneuverability, and reduces the risk of damage to the propeller and rudder.

Ship Rudder

A CFD-optimized ship rudder offers numerous benefits. These include enhanced maneuverability and safety, increased fuel efficiency due to reduced drag and improved hydrodynamic performance, and the ability to reduce noise and vibrations.

This contributes to cost savings, environmental friendliness, and improved onboard comfort, making it essential for more efficient and sustainable sailing.