- English

- Nederlands

Wind-Assisted Propulsion System (WASP)

A wind-assisted propulsion system (WASP) provides seagoing vessels with additional thrust using rotor sails, wing sails, suction sails or kites. It converts wind energy directly into propulsion, which reduces the power delivered by the main engine. This lowers fuel consumption and carbon dioxide (CO2) per ton-mile and demonstrably increases operational efficiency. The suction sail is a variant that optimizes airflow by means of active suction and thereby delivers additional yield from wind energy.

Suction Sail for Seagoing Vessels

Since 2023, wind-assisted systems have been included in the Carbon Intensity Indicator (CII) of MARPOL Annex VI, which formally recognizes them within international shipping regulation. Depending on route, loading condition and wind conditions, reductions of approximately 5 to 10% are achievable in practice. Under favorable conditions this can be higher. Investment in wind-assisted propulsion is therefore not only sustainable, but, depending on documentation and approval, can be fully compliant within the applicable MARPOL Annex VI frameworks. A wind-assisted propulsion system demonstrably strengthens both operational efficiency and the compliance position. In this way these systems contribute to lower operating costs and to the climate objectives of the International Maritime Organization (IMO) for 2030, 2040 and the ambition for net zero in 2050.

At the same time, the significance of European policy instruments is increasing. Since 2024, fuel intensity has been settled financially under the European Emissions Trading System (EU ETS), and as of January 1, 2025, FuelEU Maritime will enter into force. As a result, the link between technology and regulation is becoming increasingly direct.

Within this framework, the suction sail of our partner is considered a variant of the wind-assisted propulsion system that uses active suction to increase aerodynamic efficiency. The system combines characteristics of wing sails and rotor sails and can, depending on route, loading condition and wind conditions, according to manufacturer data, deliver up to approximately 40% reduction in CO2 emissions under ideal conditions. In regular operation, independent measurements confirm consistent reductions whose magnitude varies by route and loading condition. This creates a real opportunity for shipping companies and shipowners to achieve emission reductions and cost savings, while at the same time demonstrably strengthening the position toward EU ETS, FuelEU Maritime and CII. In this way the suction sail supports the transition to a fleet that complies with increasingly stringent international emission rules.

Operating Principle of the Suction Sail

The suction sail is a type of wind-assisted propulsion system that uses the boundary layer suction principle, an aerodynamic concept rooted in aviation. In conventional wings the airflow separates at higher angles of attack, which leads to turbulence and loss of lift. The suction sail prevents this by drawing air through openings in the profile, which keeps the boundary layer attached for longer and optimally utilizes the flow. The result is a more stable and efficient lift profile, even under conditions in which conventional sails lose performance.

This can lead to a significantly higher lift-to-drag ratio. In wind tunnel tests and Computational Fluid Dynamics (CFD) simulations, the manufacturer reported, in specific configurations, lift levels that were six to seven times higher than those of a conventional wing sail. These test data have been verified in practice according to recognized measurement protocols, with results showing that performance depends on profile, scale and operating conditions. For vessels this means that the same speed can be maintained with significantly less engine power. This creates a direct link between fuel savings and emission reductions. In this way the suction sail proves itself not only technically, but also strengthens the economic and ecological business case of the fleet.

In addition to performance, there is a focus on simplicity. The design operates autonomously, contains only a few moving parts and requires little maintenance. As a result, the system can operate reliably with minimal crew input and predictable operating costs. Its modular design also means it can be integrated in both newbuilds and retrofit projects without extensive modifications to the machinery. This makes the suction sail a flexible solution that can be deployed at scale on a wide range of vessel types, from bulk carriers and tankers to passenger vessels.

The technology builds on earlier innovations and continues that development. An important precursor was the Turbosail of the 1980s, a so-called aspirated wing that showed multiple lift improvements compared to a conventional profile. The current generation combines this principle with CFD and extensive wind tunnel validation. CFD simulates three-dimensional flow patterns under varying conditions, after which wind tunnel tests confirm the calculated performance. This provides a solid basis of digital modeling and practical verification, with reproducible performance in operational practice.

Comparison with Other Wind-Assisted Propulsion Systems

The suction sail distinguishes itself from other wind-assisted propulsion systems through active suction, a principle that can lead to higher performance and broader applicability under both test and operational conditions. As a result, the technology can deliver an equivalent contribution in diverse operational contexts, and in specific situations even add extra value compared to conventional variants.

Rotor sails use the Magnus effect, where a rotating cylinder generates lift perpendicular to the wind direction. Although this can produce significant propulsion, it also entails rotating masses, heavy foundations and higher structural loading. Under comparable conditions, the suction sail can deliver an equivalent contribution, but without these rotating components. This makes it an option for vessels with limited stability margins or deck space, where this form of wind-assisted propulsion offers a practical alternative.

Wing sails are strongly dependent on large surface area and complex trim systems. Thanks to active suction, the suction sail achieves a higher lift-to-drag ratio under certain conditions, so a more compact profile often suffices in practice. This preserves valuable deck space and allows the system to deliver demonstrable advantages precisely at variable wind angles and lower wind speeds, which are common in short-sea shipping. In this way this form of wind-assisted propulsion proves its practical significance in regular operation.

Kites exploit wind at higher altitude, where flows are stronger. Operationally, however, they are often limited, for example during port maneuvers or in bad weather. In that respect the suction sail is a more consistent alternative, permanently available, fully integrated and autonomous. This provides a predictable contribution to fuel and emission reductions, with minimal dependence on crew input.

Characteristics and Onboard Integration

This wind-assisted propulsion system is distinguished by a compact, aerodynamically optimized profile combined with an installation interface similar to that of a deck crane. This keeps integration into the vessel design straightforward and makes classification approval more predictable.

A second characteristic is the simplicity of operation. The system is fully automated and contains only a few moving parts, which limits wear and susceptibility to failure. It is driven by durable electric motors with low energy consumption and long service life. Operating costs are therefore readily predictable and unexpected maintenance needs minimal. Maintenance can generally be aligned with scheduled dry-docking, so additional downtime is avoided.

Thanks to the combination of compact design, autonomous operation and practical integration options, the suction sail is considered a scalable and future-proof solution. It can be applied in diverse fleet strategies, from bulk and tanker shipping to passenger vessels. In this way the system not only contributes to operational efficiency, but also provides a practical route to compliance with increasingly stringent international emission rules.

Automation and Control System

Control of the suction sail is fully automated and based on a closed-loop architecture. This structure is continuously fed by real-time data on wind direction, wind speed, vessel speed and course. Based on these data, three parameters are coordinated: the rotation of the main structure, the angle of the trailing-edge flap and the degree of air suction within the profile. As a result, the system responds directly to changing conditions and optimizes aerodynamic efficiency.

Thanks to this integrated control, the suction sail automatically adapts to changing conditions and keeps the lift-to-drag ratio at a high level. In this way, wind-assisted propulsion delivers predictable performance with minimal crew input. The result is consistent and reproducible performance, regardless of variations in route or weather conditions. This reduces reliance on manual operation by the crew to almost zero and creates a predictable performance pattern that simplifies day-to-day operations.

This combination not only increases reliability and safety, but also makes the system easy to integrate into existing onboard operational and safety protocols. In this way, automation forms a crucial link in the practical applicability of the suction sail, both for newbuilds and for retrofit projects.

Available Variants

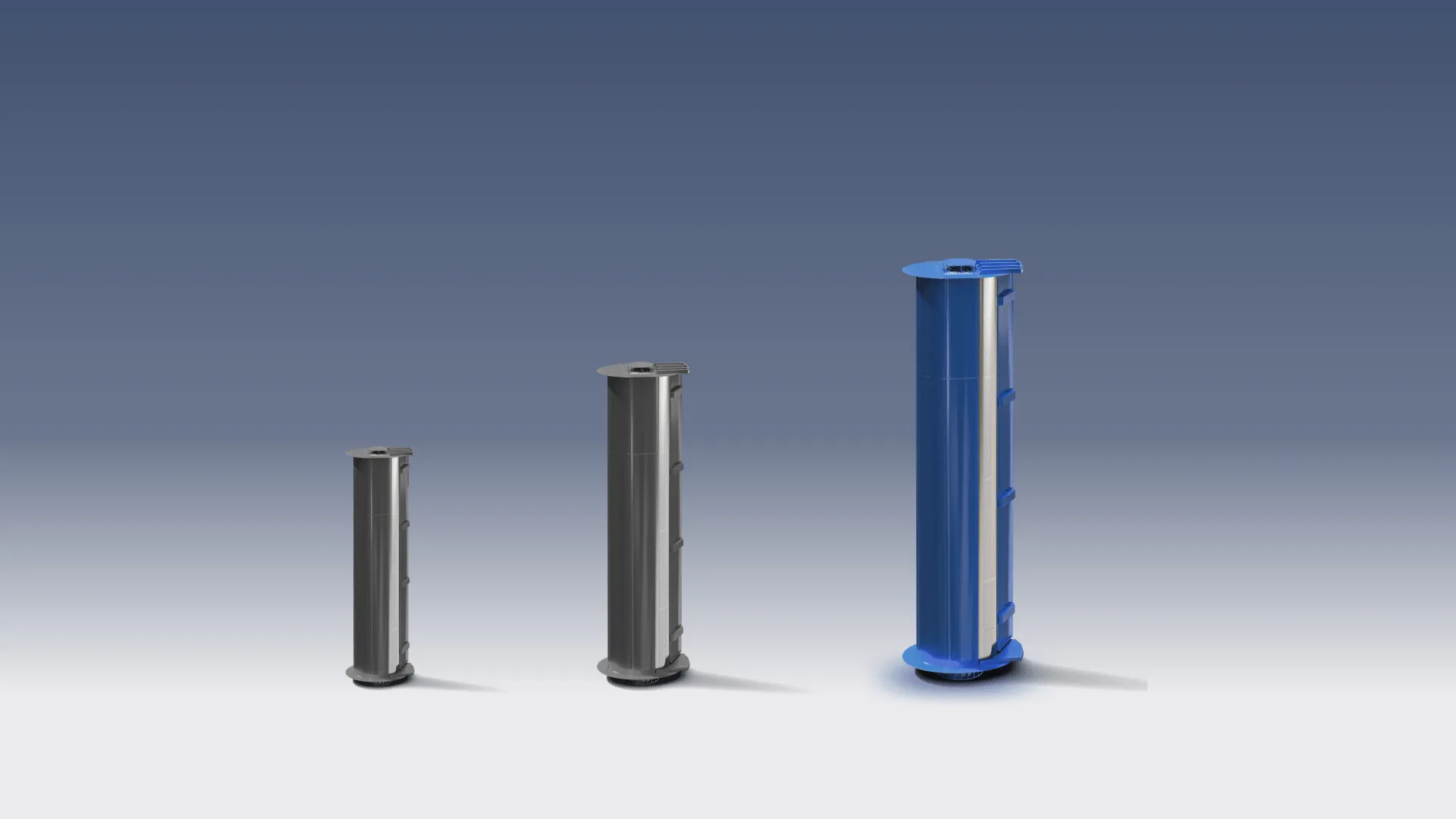

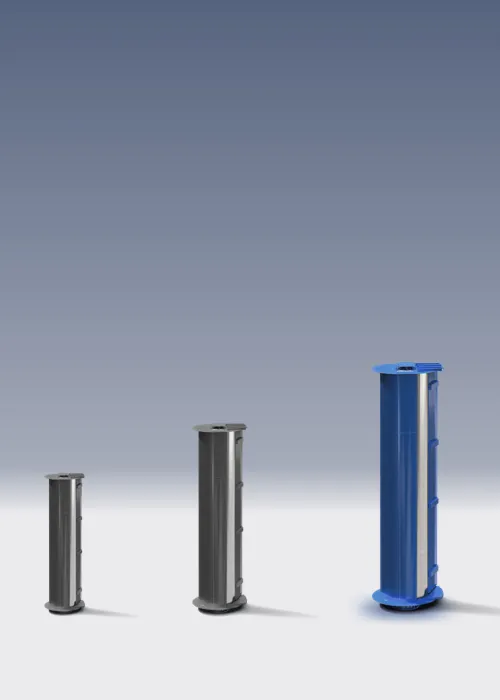

This wind-assisted propulsion system is modular by design and supplied in three configurations, so the technology can be closely tailored to different vessel types and operational profiles. This makes the system deployable in both short-sea and deep-sea shipping, without compromising safety or integration into the vessel design.

The range opens with the compact model, with a width of 2.85 meters and a height between 12 and 17 meters. This variant is particularly suitable for vessels with limited deck space or lower stability margins, such as short-sea cargo vessels, fishing vessels and multipurpose vessels. Due to its relatively modest dimensions, this design can be applied easily in retrofit projects. This creates a practical solution for vessels operating in shallow waters or busy waterways, where maneuverability and robustness are crucial.

The medium variant is the next step, with a width of 4.5 meters and a height between 18 and 26 meters. This configuration has been developed for vessel types such as Handysize bulk carriers, Medium Range and Long Range 1 tankers, Panamax vessels, ferries and roll-on/roll-off (RoRo) vessels. Compared to the compact model, this design delivers significantly more thrust, while structural loading for the vessel remains manageable. This creates a balanced solution that offers higher performance without making integration unnecessarily complex.

At the top of the range is the large configuration, with a width of 6 meters and a height varying from 24 to 36 meters. This model is specifically developed for heavy-class vessels, including Aframax, Suezmax, Kamsarmax and Capesize vessels, as well as Very Large Crude Carriers (VLCC). Thanks to its scale and aerodynamic efficiency, this variant can achieve substantial reductions in fuel consumption and emissions. This makes this type of wind-assisted propulsion system particularly attractive on long-haul routes, where structural efficiency gains have a direct impact on cost and emission profiles.

All variants are optionally available with a tilting feature. With this function, the mast can be lowered in case of height restrictions, for example during bridge passages or port approaches. This creates additional operational flexibility worldwide, while day-to-day operations can continue uninterrupted.

Wind-Assisted Propulsion System (WASP)

A wind-assisted propulsion system (WASP) provides vessels with additional thrust using rotor sails, wing sails, suction sails or kites. It converts wind energy into propulsion and reduces fuel and CO2 per ton-mile. The suction sail uses active suction to increase the yield from wind energy.

Suction Sail for Seagoing Vessels

Since 2023, wind-assisted systems have been included in the Carbon Intensity Indicator (CII) of MARPOL Annex VI, which formally recognizes them within international shipping regulation. Depending on route, loading condition and wind conditions, reductions of approximately 5 to 10% are achievable in practice. Under favorable conditions this can be higher. Investment in wind-assisted propulsion is therefore not only sustainable, but, depending on documentation and approval, can be fully compliant within the applicable MARPOL Annex VI frameworks. A wind-assisted propulsion system demonstrably strengthens both operational efficiency and the compliance position. In this way these systems contribute to lower operating costs and to the climate objectives of the International Maritime Organization (IMO) for 2030, 2040 and the ambition for net zero in 2050.

At the same time, the significance of European policy instruments is increasing. Since 2024, fuel intensity has been settled financially under the European Emissions Trading System (EU ETS), and as of January 1, 2025, FuelEU Maritime will enter into force. As a result, the link between technology and regulation is becoming increasingly direct.

Within this framework, the suction sail of our partner is considered a variant of the wind-assisted propulsion system that uses active suction to increase aerodynamic efficiency. The system combines characteristics of wing sails and rotor sails and can, depending on route, loading condition and wind conditions, according to manufacturer data, deliver up to approximately 40% reduction in CO2 emissions under ideal conditions. In regular operation, independent measurements confirm consistent reductions whose magnitude varies by route and loading condition. This creates a real opportunity for shipping companies and shipowners to achieve emission reductions and cost savings, while at the same time demonstrably strengthening the position toward EU ETS, FuelEU Maritime and CII. In this way the suction sail supports the transition to a fleet that complies with increasingly stringent international emission rules.

Operating Principle of the Suction Sail

The suction sail is a type of wind-assisted propulsion system that uses the boundary layer suction principle, an aerodynamic concept rooted in aviation. In conventional wings the airflow separates at higher angles of attack, which leads to turbulence and loss of lift. The suction sail prevents this by drawing air through openings in the profile, which keeps the boundary layer attached for longer and optimally utilizes the flow. The result is a more stable and efficient lift profile, even under conditions in which conventional sails lose performance.

This can lead to a significantly higher lift-to-drag ratio. In wind tunnel tests and Computational Fluid Dynamics (CFD) simulations, the manufacturer reported, in specific configurations, lift levels that were six to seven times higher than those of a conventional wing sail. These test data have been verified in practice according to recognized measurement protocols, with results showing that performance depends on profile, scale and operating conditions. For vessels this means that the same speed can be maintained with significantly less engine power. This creates a direct link between fuel savings and emission reductions. In this way the suction sail proves itself not only technically, but also strengthens the economic and ecological business case of the fleet.

In addition to performance, there is a focus on simplicity. The design operates autonomously, contains only a few moving parts and requires little maintenance. As a result, the system can operate reliably with minimal crew input and predictable operating costs. Its modular design also means it can be integrated in both newbuilds and retrofit projects without extensive modifications to the machinery. This makes the suction sail a flexible solution that can be deployed at scale on a wide range of vessel types, from bulk carriers and tankers to passenger vessels.

The technology builds on earlier innovations and continues that development. An important precursor was the Turbosail of the 1980s, a so-called aspirated wing that showed multiple lift improvements compared to a conventional profile. The current generation combines this principle with CFD and extensive wind tunnel validation. CFD simulates three-dimensional flow patterns under varying conditions, after which wind tunnel tests confirm the calculated performance. This provides a solid basis of digital modeling and practical verification, with reproducible performance in operational practice.

Comparison with Other Wind-Assisted Propulsion Systems

The suction sail distinguishes itself from other wind-assisted propulsion systems through active suction, a principle that can lead to higher performance and broader applicability under both test and operational conditions. As a result, the technology can deliver an equivalent contribution in diverse operational contexts, and in specific situations even add extra value compared to conventional variants.

Rotor sails use the Magnus effect, where a rotating cylinder generates lift perpendicular to the wind direction. Although this can produce significant propulsion, it also entails rotating masses, heavy foundations and higher structural loading. Under comparable conditions, the suction sail can deliver an equivalent contribution, but without these rotating components. This makes it an option for vessels with limited stability margins or deck space, where this form of wind-assisted propulsion offers a practical alternative.

Wing sails are strongly dependent on large surface area and complex trim systems. Thanks to active suction, the suction sail achieves a higher lift-to-drag ratio under certain conditions, so a more compact profile often suffices in practice. This preserves valuable deck space and allows the system to deliver demonstrable advantages precisely at variable wind angles and lower wind speeds, which are common in short-sea shipping. In this way this form of wind-assisted propulsion proves its practical significance in regular operation.

Kites exploit wind at higher altitude, where flows are stronger. Operationally, however, they are often limited, for example during port maneuvers or in bad weather. In that respect the suction sail is a more consistent alternative, permanently available, fully integrated and autonomous. This provides a predictable contribution to fuel and emission reductions, with minimal dependence on crew input.

Characteristics and Onboard Integration

This wind-assisted propulsion system is distinguished by a compact, aerodynamically optimized profile combined with an installation interface similar to that of a deck crane. This keeps integration into the vessel design straightforward and makes classification approval more predictable.

A second characteristic is the simplicity of operation. The system is fully automated and contains only a few moving parts, which limits wear and susceptibility to failure. It is driven by durable electric motors with low energy consumption and long service life. Operating costs are therefore readily predictable and unexpected maintenance needs minimal. Maintenance can generally be aligned with scheduled dry-docking, so additional downtime is avoided.

Thanks to the combination of compact design, autonomous operation and practical integration options, the suction sail is considered a scalable and future-proof solution. It can be applied in diverse fleet strategies, from bulk and tanker shipping to passenger vessels. In this way the system not only contributes to operational efficiency, but also provides a practical route to compliance with increasingly stringent international emission rules.

Automation and Control System

Control of the suction sail is fully automated and based on a closed-loop architecture. This structure is continuously fed by real-time data on wind direction, wind speed, vessel speed and course. Based on these data, three parameters are coordinated: the rotation of the main structure, the angle of the trailing-edge flap and the degree of air suction within the profile. As a result, the system responds directly to changing conditions and optimizes aerodynamic efficiency.

Thanks to this integrated control, the suction sail automatically adapts to changing conditions and keeps the lift-to-drag ratio at a high level. In this way, wind-assisted propulsion delivers predictable performance with minimal crew input. The result is consistent and reproducible performance, regardless of variations in route or weather conditions. This reduces reliance on manual operation by the crew to almost zero and creates a predictable performance pattern that simplifies day-to-day operations.

This combination not only increases reliability and safety, but also makes the system easy to integrate into existing onboard operational and safety protocols. In this way, automation forms a crucial link in the practical applicability of the suction sail, both for newbuilds and for retrofit projects.

Available Variants

This wind-assisted propulsion system is modular by design and supplied in three configurations, so the technology can be closely tailored to different vessel types and operational profiles. This makes the system deployable in both short-sea and deep-sea shipping, without compromising safety or integration into the vessel design.

The range opens with the compact model, with a width of 2.85 meters and a height between 12 and 17 meters. This variant is particularly suitable for vessels with limited deck space or lower stability margins, such as short-sea cargo vessels, fishing vessels and multipurpose vessels. Due to its relatively modest dimensions, this design can be applied easily in retrofit projects. This creates a practical solution for vessels operating in shallow waters or busy waterways, where maneuverability and robustness are crucial.

The medium variant is the next step, with a width of 4.5 meters and a height between 18 and 26 meters. This configuration has been developed for vessel types such as Handysize bulk carriers, Medium Range and Long Range 1 tankers, Panamax vessels, ferries and roll-on/roll-off (RoRo) vessels. Compared to the compact model, this design delivers significantly more thrust, while structural loading for the vessel remains manageable. This creates a balanced solution that offers higher performance without making integration unnecessarily complex.

At the top of the range is the large configuration, with a width of 6 meters and a height varying from 24 to 36 meters. This model is specifically developed for heavy-class vessels, including Aframax, Suezmax, Kamsarmax and Capesize vessels, as well as Very Large Crude Carriers (VLCC). Thanks to its scale and aerodynamic efficiency, this variant can achieve substantial reductions in fuel consumption and emissions. This makes this type of wind-assisted propulsion system particularly attractive on long-haul routes, where structural efficiency gains have a direct impact on cost and emission profiles.

All variants are optionally available with a tilting feature. With this function, the mast can be lowered in case of height restrictions, for example during bridge passages or port approaches. This creates additional operational flexibility worldwide, while day-to-day operations can continue uninterrupted.

In Practice: Pioneer Project in Short-Sea Shipping

In July 2023, a North Holland shipping company installed two 17-meter suction sails on an existing short-sea cargo vessel, as visible in the photo below. This realized the largest application to date of this type of wind-assisted propulsion on a general cargo ship. The result prompted a follow-up order: in mid-2025 a suction sail with a height of 22 meters will be installed in the same fleet. With these initiatives, the shipping company confirms its commitment to sustainable and efficient shipping, with demonstrable emission reduction and compliance with increasingly stringent regulation.

In Practice: Pioneer Project in Short-Sea Shipping

In July 2023, a North Holland shipping company installed two 17-meter suction sails on an existing short-sea cargo vessel, as visible in the photo below. This realized the largest application to date of this type of wind-assisted propulsion on a general cargo ship. The result prompted a follow-up order: in mid-2025 a suction sail with a height of 22 meters will be installed in the same fleet. With these initiatives, the shipping company confirms its commitment to sustainable and efficient shipping, with demonstrable emission reduction and compliance with increasingly stringent regulation.

FAQ on Wind-Assisted Propulsion and Suction Sails: Technology, Regulation, Financing and Operational Deployment

These Frequently Asked Questions (FAQ) provide an integrated overview of how wind-assisted propulsion with the suction sail contributes to the decarbonization of seaborne transport. The technology reduces the propulsion power required and thereby lowers fuel consumption and emissions. As a result, costs under the European Emissions Trading System (EU ETS) decrease, compliance with FuelEU Maritime becomes simpler and scores within the Energy Efficiency Existing Ship Index (EEXI) and the Carbon Intensity Indicator (CII) improve. For shipping companies and shipowners, this makes it clear that a technical innovation delivers not only operational benefits but also financial and policy gains.

In addition, this FAQ addresses the broader context in which a suction sail is applied. Topics include operational integration onboard and in port, the requirements of classification societies and international safety codes, and embedding in the International Safety Management (ISM) system and the Ship Energy Efficiency Management Plan Part III (SEEMP III). Technical validation is also addressed, as is the need for a complete audit trail, among other things via ISO 15016 and the Monitoring, Reporting and Verification (MRV) dataset. This shows how technology, compliance and governance reinforce each other in daily practice.

Finally, this FAQ discusses the financial and policy framework conditions for large-scale deployment. European and national subsidies, fiscal schemes, port fee discounts and private financing under the Poseidon Principles and the EU Taxonomy are placed within the state aid framework. The result is an integrated picture in which technology, regulation, financing and operations converge, with the aim of supporting the development of a legally robust and future-proof fleet.

Regulation and Compliance

What Does EU ETS Participation Cost With a Suction Sail, and How Do I Pass On Those Costs?

Core: EU ETS costs are calculated based on MRV emissions, phase-in percentage, scope factor and EUA price (€/ton). A suction sail can demonstrably reduce CO2 emissions, subject to verification and flag state acceptance. This can lower the compliance payment under the EU ETS, with potential strategic cost reduction. Audit and reporting obligations remain fully in force under all circumstances.

Detailed: Costs within the European Emissions Trading System (EU ETS) are determined on the basis of reported emissions in tons of carbon dioxide (CO2), multiplied by three factors, the scope, the phase-in percentage and the current price of emission allowances, European Union Allowances (EUAs). Since 2024, a rising obligation applies in which 40% of emissions are settled in 2024, 70% in 2025 and the full 100% from 2026. The first settlement, surrender of emission allowances, takes place no later than September 30, 2025, for the emissions of the year 2024. For scope, intra-EU voyages count in full, voyages between EU and non-EU ports count 50%, and emissions at berth count in full.

This methodology can be summarized in a simple calculation structure. ETS costs in euros equal reported CO2 in tons multiplied by the chosen scope factor, the phase-in percentage and the current EUA price in euro per ton. The scope factor is 1.00 for intra-EU voyages and at-berth emissions, and 0.50 for voyages to or from non-EU ports. The phase-in percentage grows linearly from 0.40 in 2024 to 1.00 from 2026. The Monitoring, Reporting and Verification (MRV) dataset has included, since January 1, 2024, not only CO2, but also methane (CH4) and nitrous oxide (N2O).

The suction sail offers a direct advantage, because demonstrated fuel and emission savings are deducted directly from the report. This reduces the ETS payment and means the system delivers not only operational fuel savings, but also financial relief.

A practical example makes this concrete. When a vessel in 2025 reports 3,000 tons of CO2 during an intra-EU voyage, this leads, at a phase-in percentage of 70% and an EUA price of €80 per ton, to an ETS payment of approximately €168,000. If, in the same year, a voyage is performed from the EU to a non-EU port with emissions of 5,000 tons of CO2, then under the same conditions this results in an ETS cost item of about €140,000. For emissions at berth, for example 200 tons of CO2, this in this scenario amounts to approximately €11,200. This makes it clear that every ton of CO2 avoided by deploying the suction sail not only reduces fuel consumption, but also provides direct financial relief within the EU ETS.

Is a Suction Sail Included in FuelEU Maritime, and Can I Pool or Bank?

Core: FuelEU Maritime can include wind assistance via a suction sail in the calculation of well-to-wake intensity. This reduction can demonstrably contribute to compliance obligations and operational cost reduction. Banking, borrowing and pooling are permitted subject to conditions and can increase strategic flexibility. Audit and verification remain mandatory for acceptance within FuelEU Maritime.

Detailed: Yes, wind assistance via a suction sail counts within FuelEU Maritime, which takes effect as of January 1, 2025. This technology-neutral framework does not assess the installation itself, but the well-to-wake intensity of the energy used onboard. This intensity is expressed in grams of CO2 equivalent per megajoule (g CO2e/MJ). Because a suction sail reduces the propulsion power required and thereby the average greenhouse gas intensity, the contribution is included directly in the calculation. This makes wind-assisted propulsion both recognized in policy terms and practically deployable within the fleet strategy of shipping companies.

FuelEU Maritime includes three mechanisms that enable flexibility in compliance. Banking allows surpluses to be carried over to a subsequent year. Borrowing offers the option to compensate a temporary shortfall with performance from a future year, with a payback factor above 1.00. Pooling, lastly, makes it possible to bundle the performance of multiple vessels, provided the overall balance is positive. Each vessel can participate in only one pool per year. This participation is recorded in the FuelEU Maritime database and confirmed by an independent verifier. In this way, the value of a suction sail can be utilized across the fleet.

In terms of scope, FuelEU Maritime aligns with the European Emissions Trading System (EU ETS). For voyages within the EU and the European Economic Area (EEA), 100% of energy consumption counts, while voyages between the EU or EEA and third countries count 50%. Energy consumption at berth is included in full. The reduction targets rise stepwise, 2% in 2025, 6% in 2030, 14.5% in 2035, 31% in 2040, 62% in 2045 and 80% in 2050, each relative to the reference value of 91.16 g CO2e/MJ. A suction sail thus becomes a tangible tool to make compliance with these increasingly stringent requirements simpler and more cost-effective.

For reliable application, it is crucial that calculations and internal reporting align fully with the MRV methodology. The monitoring plan must explicitly include the operation of wind assistance and the relevant parameters, so that audit trails are transparent and reproducible. In this way, the contribution of the suction sail can be convincingly included in the FuelEU Maritime balance, the Document of Compliance (DoC) and, if applicable, within a pool structure.

How Does a Suction Sail Count Toward the Energy Efficiency Existing Ship Index (EEXI)?

Core: The Energy Efficiency Existing Ship Index (EEXI) can include a suction sail under conditions via the route for innovative technologies. With a wind force matrix, the reduction in required engine power can be calculated demonstrably. After verification and class acceptance, this can lead to a lower design power and a more favorable EEXI score. Audit and the flag state authority retain full assessment authority.

Detailed: Within the Energy Efficiency Existing Ship Index (EEXI), a suction sail can only be included via the route for innovative technologies. This route is intended for systems that demonstrably improve energy efficiency, but that do not fall under the standard calculation methods. For wind assistance, this is done using a wind force matrix, a calculation model that quantifies the effect of the system on the required design power of the main engine. The classification society assesses this matrix and must formally approve it before the outcome can be included in the EEXI file. If assumptions and verification are solid, this can lead to a lower calculated required design power and thus to a more favorable index score.

The distinction with the Carbon Intensity Indicator (CII) is important. The EEXI is a one-off, design-based index that, at the first assessment of a vessel, determines whether it meets the efficiency requirements of MARPOL Annex VI. The CII, by contrast, is an annual, operational index that measures actual carbon intensity, expressed in grams of CO2 per ton-mile (g/ton-mile), based on the MRV system, and categorizes vessels in performance classes. For shipping companies, this means that a suction sail can deliver advantages not only on paper via a better EEXI score, but also in practice through a lower annual CII value.

For EEXI documentation, a complete and consistent file is needed. This includes the technical system data of the suction sail, the wind force matrix used, results of tests and validation, such as Computational Fluid Dynamics (CFD) and wind tunnel measurements, and the verification method applied. All assumptions must align fully with the actual configuration and the operational limitations of the onboard system. This prevents debate during later audits and keeps the credibility of performance claims toward the classification society and flag state authority firmly underpinned.

How Do I Integrate a Suction Sail Into SEEMP III, EU-MRV and IMO-DCS?

Core: SEEMP III, EU-MRV and IMO-DCS can secure suction sail integration for compliance, reduction and emissions. SEEMP III can under conditions specify monitoring, management and audit processes, including cost allocation, reporting frameworks and internal controls for MRV, EU ETS and CII. EU-MRV can, depending on the monitoring plan, record CO2, CH4 and N2O, which means demonstrable reduction and compliance insights influence costs and emissions. IMO-DCS can ensure data alignment with MRV. A suction sail can under conditions deliver auditable reduction, with positive cost and compliance implications.

Detailed: Deployment of a suction sail must be not only technically and operationally robust, but also fully aligned with the mandatory reporting frameworks. The Ship Energy Efficiency Management Plan Part III (SEEMP III) is the starting point. In this plan, the shipping company records how the system is operated, which parameters are monitored and how performance is verified. SEEMP III is dynamic and must be reviewed annually to incorporate changes in routes, configurations or reduction targets. This makes the operation of the suction sail a formal part of the energy-efficiency management of the fleet.

The European Union’s MRV dataset serves as the central data source. Since January 1, 2024, this includes, in addition to carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O). The same dataset feeds both settlement under the EU ETS and calculation of greenhouse gas intensity within FuelEU Maritime. For the shipping company, this means that one dataset supports multiple obligations, provided data quality, definitions and consistency are properly assured.

In parallel, the obligation under the Data Collection System (DCS) of the International Maritime Organization (IMO) applies, which annually collects fuel and voyage data from vessels above 5,000 GT worldwide. Although DCS is formally separate from EU-MRV, it requires consistent use of definitions and data selections. Deviations between the two streams lead to questions from auditors and can undermine the reliability of the reports.

It is important to distinguish this from the Energy Efficiency Existing Ship Index (EEXI). The EEXI is a one-off, design-based test that is established only at the first assessment of a vessel. Annual datasets from SEEMP III, MRV and DCS do not affect it, but they do determine operational frameworks such as the Carbon Intensity Indicator (CII), EU ETS and FuelEU Maritime.

Operationally, you work most robustly with one single source of truth, an integrated data platform in which shaft power, fuel flow, true and apparent wind and the suction power of the suction sail are recorded at sufficient resolution. By linking these data directly to internal ETS processes and MRV-validated tonnages, a transparent audit trail emerges. This makes internal controls more efficient and external verifications predictable.

The result is a closed chain from measurement to compliance, with SEEMP III serving as the operational framework, MRV as the dataset for European obligations and DCS as the global complement. This means regulation is not only met, but a solid foundation is also created for strategic decision-making on fuel choice, route planning and fleet optimization.

Charterparty and P&I: How Do You Allocate Risks and Responsibilities?

Core: Charterparties and P&I can be influenced legally and financially by a suction sail. The charterparty must, under conditions, state clearly who purchases emission allowances under the EU ETS and how CII risks and EEXI measures are allocated. For P&I, coverage can depend on demonstrable MRV compliance and verification of emission reduction. Transparent arrangements on data, monitoring and audit can limit disputes and support cost control.

Detailed: Deployment of a suction sail has direct consequences for charterparties, agreements between owner and charterer of a vessel, and for coverage via Protection and Indemnity (P&I) clubs, the maritime insurers that cover liability and claims. For the European Emissions Trading System (EU ETS), the principle generally applies that the party paying for the fuel is responsible for emission allowances (EUAs). The charterparty must therefore explicitly record which party purchases and surrenders the allowances.

For the Carbon Intensity Indicator (CII), cooperation is essential. The CII measures annual carbon intensity in grams of CO2 per ton-mile (g/ton-mile), emissions per transported ton of cargo per nautical mile. Factors such as speed, route choice and waiting times have a direct influence. Charter agreements therefore often include joint arrangements, frequently with a contingency plan for when a vessel risks falling back to a lower CII rating. That plan can include additional operational measures as well as the deployment of additional suction sails.

For the Energy Efficiency Existing Ship Index (EEXI), a one-off design index, measures such as Engine Power Limitation (EPL), limiting engine power, or installation of shaft-power monitoring must be explicitly included in the agreement. Transparency is crucial. Arrangements on data access and reporting must be clear in advance, so that classification societies and auditors can assess compliance without debate.

For P&I coverage, it is important that fines or claims due to non-compliance are explicitly addressed in the policy. Some insurers exclude this, while others provide coverage provided the shipping company can demonstrate that reasonable measures have been taken. The evidence must align fully with the data from the European Union’s MRV system. In this way, it can be convincingly demonstrated that emission reductions due to the suction sail have been correctly recorded and stand up legally in the event of disputes.

How Does a Suction Sail Support Fuels Such as Methanol or Bio-LNG?

Core: FuelEU Maritime can include a suction sail as a structural reduction of well-to-wake intensity and fuel costs. The system can make the deployment of alternative fuels such as methanol and bio-LNG more attractive financially and operationally. MRV data can, under conditions, secure demonstrable reductions and lower EU ETS and FuelEU Maritime burdens. Audit and class verification can remain necessary for full compliance and insurable application.

Detailed: A suction sail reduces the propulsion power required and thereby the absolute fuel consumption of a vessel. This principle applies not only to conventional oil products such as very low sulfur fuel oil (VLSFO) or marine gas oil (MGO), but also to alternative fuels. Examples include methanol, fossil or renewable, including bio-methanol and e-methanol, which is produced synthetically using renewable electricity without fossil input, bio-LNG, which consists of liquefied biogenic natural gas, and hydrogen carriers such as ammonia or liquid organic hydrogen carriers (LOHCs). Since these fuels are generally two to four times more expensive than VLSFO, every percentage of fuel saved translates directly into lower operating costs. For fossil methanol, the CO2 intensity is comparable to conventional fuels. A policy advantage arises only with bio or e variants. This creates a financial lever that accelerates the switch to cleaner but more expensive fuels.

Regulation also plays a decisive role. The FuelEU Maritime framework, which takes effect in 2025, does not look at the presence of a suction sail as a technology, but at the well-to-wake intensity of onboard energy. This intensity is expressed in grams of CO2 equivalent per megajoule (g CO2e/MJ). A suction sail lowers the energy consumption required per nautical mile, which automatically decreases the average intensity. This directly supports compliance with the reduction targets, 2% in 2025, 6% in 2030, 14.5% in 2035, 31% in 2040, 62% in 2045 and 80% in 2050, each relative to the reference value of 91.16 g CO2e/MJ. In this way, wind-assisted propulsion becomes a policy-recognized tool that makes the deployment of alternative fuels significantly more cost-effective.

For vessels using Renewable Fuels of Non-Biological Origin (RFNBOs), such as e-methanol or e-ammonia, there is an additional effect. FuelEU Maritime contains a conditional obligation. Only if, in 2031, it appears that fleet-wide use of RFNBOs is below 1%, will a minimum share of 2% apply as of 2034. Because a suction sail lowers the absolute fuel volume, less RFNBO must be physically bunkered to meet the same relative target. This reduces both fuel costs and logistical pressure in ports where availability is limited.

An example calculation illustrates the impact. Suppose a vessel runs entirely on e-methanol at a price of €1,200 per ton, on average three times higher than VLSFO in 2025. A suction sail that saves 10% fuel at an annual consumption of 20,000 tons avoids 2,000 tons of bunkering. This results in a direct cost saving of €2.4 million per year, excluding additional benefits. The same fuel saving is recorded in the MRV dataset, which feeds both the EU ETS payment and the FuelEU Maritime intensity. In this way, one consistent dataset leads to a double compliance gain, lower emission costs under the European Emissions Trading System (EU ETS) and simpler compliance with FuelEU Maritime.

For assurance, it is essential that the savings are verified according to a recognized protocol, such as ISO 15016 or an equivalent framework accepted by classification societies. This makes performance claims reproducible in audits and suitable for inclusion in financing or subsidy applications. This creates a closed chain from technology to compliance, governance and decision-making. This makes the combination of a suction sail and alternative fuels a strategically robust route, technically proven, financially attractive, policy-recognized and audit-proof.

How Do Subsidies for Suction Sails Fit Within the European State Aid Framework?

Core: The European state aid framework can allow subsidies for wind-assisted propulsion if proportionality, transparency and cost reduction are demonstrable. Only additional costs above the conventional reference can be eligible for subsidies, depending on verification and audit. Double counting with fiscal schemes such as MIA, Vamil and EIA can be excluded. Subject to EU approval, support can facilitate compliance and strategic investments.

Detailed: Public support for wind-assisted propulsion must always fit within the European state aid framework. This is shaped by the General Block Exemption Regulation (GBER) and by the European Commission’s Temporary Crisis and Transition Framework (TCTF), which was established to accelerate the green transition. Both regimes allow room for financial support, while imposing strict conditions aimed at transparency, proportionality and preventing overcompensation.

For shipping companies and shipowners, this means that the additional costs of an installation compared to a conventional reference, for example a vessel without wind-assist technology, must be substantiated convincingly. Only that portion of the costs is eligible for subsidies, which makes it visible that support is necessary to make the investment feasible and does not lead to undue advantage. Double counting with other schemes, such as fiscal benefits via the Environmental Investment Allowance (MIA), the Random Depreciation of Environmental Investments (Vamil) or the Energy Investment Allowance (EIA), must be explicitly excluded.

These rules create a solid legal foundation. Subsidies are thus deployed effectively to bring innovative technologies such as suction sails into service faster, while remaining legally sustainable in later inspections by supervisors or in a potential review by the European Commission. This provides certainty to both investor and grantor, while the sector as a whole benefits from a level playing field.

How Do You Make Subsidies and Financing for Suction Sails Audit Proof?

Core: Subsidies and financing can be made audit-proof by verifying reduction and compliance via ISO 15016 or an equivalent class-accepted protocol. One consistent dataset can, under conditions, support subsidies, EU ETS and FuelEU Maritime reporting simultaneously. Transparency and reproducible MRV data can strengthen legal robustness. Audit and flag state acceptance remain mandatory for full compliance and insurable application.

Detailed: Making subsidies and financing reliable starts with a closed, data-driven approach. The core is one consistent dataset that covers all relevant parameters, such as shaft power, fuel flow, true and apparent wind and the energy consumption of the suction sail. When these data are collected systematically and linked directly to the European Union’s Monitoring, Reporting and Verification (MRV) reporting, a transparent basis emerges that supports multiple objectives simultaneously.

It is crucial that this dataset is verified according to internationally recognized methodologies. ISO 15016, which prescribes how speed and power must be measured and corrected, provides a solid foundation for this. An equivalent protocol accepted by classification societies can also be applied. Through this verification, the reliability of the measurements is not only technically assured, but also legally sound and suitable for use in audits.

As a result, subsidy requirements, financing conditions and compliance reporting align seamlessly. A shipping company that can demonstrate that the same dataset supports both the financial substantiation of a subsidy application and compliance with the EU ETS and FuelEU Maritime has a convincing audit trail. This greatly reduces the risk of rejection, recovery or delays in the financing flow.

The result is that the internal governance of the shipping company becomes as solid as the technology on deck, transparent, reproducible and fully aligned with international standards. This turns the suction sail not only into a proven technical measure for emission reduction, but also into a financially robust investment that withstands any audit.

Technology and Performance

What Is the Energy Consumption of a Suction Sail, and How Does It Compare to the Savings?

Core: The operational energy consumption of a suction sail can be higher due to fans, but the reduction in shaft power can generally be greater. As a result, a positive net balance can arise with demonstrable fuel saving and emission reduction. Verification according to ISO 15016 or ISO 19030 can, under conditions, secure reliability. MRV data can record reductions in an audit-proof manner for EU ETS, FuelEU Maritime and CII compliance.

Detailed: The operational energy consumption of a suction sail is determined primarily by the fans that provide boundary layer suction. This requires continuous electrical power from the auxiliary generators, but the total energy balance can in practice usually be positive. The reduction in required shaft power outweighs the additional suction power in many voyage scenarios. Under favorable conditions, this enables a clear net fuel saving and emission reduction, while the crew needs to intervene only minimally. This ratio makes the suction sail attractive for shipping companies that want to combine operational efficiency and decarbonization.

The balance is verifiable via an energy account at engine level. The net gain in fuel is expressed in grams per kilowatt-hour (g/kWh), as saved shaft power multiplied by the specific fuel consumption of the main engine minus suction power multiplied by the specific fuel consumption of the auxiliary generator. Because generators can operate relatively less efficiently at low load, the outcome differs per configuration and load profile. With vessel-specific consumption maps, this can be calibrated accurately. This shows that the net saving is often positive, depending on engine and generator efficiency, loading, wind direction and speed and route choice.

In practice, most suction sails are designed to operate automatically and to be active only when this is expected to contribute efficiently to propulsion. Automatic control logic then throttles back or switches off the system under unfavorable conditions, which avoids unnecessary energy consumption and often yields a favorable net balance in practice. This ensures that the system is practically deployable across diverse voyage profiles, while the crew experiences hardly any additional workload.

For a reliable assessment, precise monitoring is essential. Trend analyses of propulsion, fuel consumption and relevant wind and sea-state parameters can be set up according to ISO 19030. Where applicable, normalization of sea trial data according to ISO 15016 can provide additional assurance. Preferably use vessel MRV data with flowmeter or mass-balance substantiation (MP/flowmeter/BDN) and record a transparent audit trail. Certification and reporting are possible subject to class acceptance and flag state acceptance. This creates a convincing substantiation that the suction sail can in practice contribute to fuel saving and economic value in audits and compliance reports.

Multi-Sail Arrays: How Do You Prevent Shadowing and Interaction?

Core: Multi-sail arrays can, via CFD analysis, optimal spacing and offset, limit shadowing and negative interactions. Higher loads can require reinforced foundations, subject to verification by class and flag state. Design choices and operational limitations can be recorded in manuals and made auditable. This can support compliance, emission reduction and cost efficiency under EEXI, CII and FuelEU Maritime.

Detailed: Installing multiple suction sails requires careful design and substantiation. In the sector, Computational Fluid Dynamics (CFD), digital simulation of three-dimensional airflow, is often used for this. CFD can calculate the optimal distance between the sails, spacing, and whether a slight lateral offset contributes to more favorable airflow. In this way, the joint thrust is optimally utilized. In addition to aerodynamic factors, practical aspects also play a role, such as keeping paths clear for cranes and lashing activities. On tankers, the manifold, the connection point for bunkering and liquid cargo transfer, receives extra attention so that this process can continue unhindered.

Onboard, a phased approach is often used. An initial installation with two suction sails provides measurement data that are then used to further refine CFD models. This enables the models to predict more accurately how multiple sails interact. When more suction sails are added, the accuracy of the calculation model increases and the shipowner can make better substantiated choices.

Because multiple sails together exert higher forces on deck and foundation, it may be necessary to stiffen the deck or reinforce the foundation. These calculations are performed per vessel and recorded in the design and safety file. The chosen arrangement, including any operational limitations at specific wind angles or loading conditions, is included in both the design and the operations manual. This demonstrates that the application meets the requirements of classification societies and is technically and operationally responsible.

Weather Routing With Wind-Assisted Propulsion: How Much Additional Savings Does It Deliver?

Core: Weather routing can increase the return of wind-assisted propulsion by aligning routes and speeds with favorable wind angles. Small speed adjustments can deliver demonstrable extra fuel and emission reduction. This can, under conditions, be measurable in KPIs and MRV data. Compliance and cost benefits can remain dependent on verification and flag state acceptance.

Detailed: Weather routing can increase the benefits of wind-assisted propulsion. By aligning route planning with favorable combinations of true wind angle, the angle between the actual wind direction and the vessel’s course, and apparent wind angle, the angle created by the vessel’s own speed relative to the wind, the suction sail can contribute more effectively to propulsion. This is achieved without jeopardizing the Estimated Time of Arrival (ETA) or agreements in the charterparty. The largest saving potential lies in small speed adjustments, because this enables more legs to be sailed under favorable wind conditions.

In operational deployment, the suction sail can be integrated into the vessel’s route planner. This software takes account of the power of the main engine, the operational limits of the suction sail and external conditions such as wave height and sea state. On that basis, alternative routes are calculated, incorporating not only voyage time but also fuel consumption and emissions.

The added value of weather routing can be shown in Key Performance Indicators (KPIs), for example by setting fuel saving and emission reduction against a standard route. The exact quantification depends on the method chosen, the data available and the operational conditions. This enables weather routing to be incorporated both operationally and strategically in fleet planning or in drafting charterparties.

Stacking and Double Counting: How Do You Avoid Overlap in Savings?

Core: Double counting can be avoided by calculating each measure marginally against an adjusted baseline. Annual waterfall analyses can make reduction allocation transparent and avoid overlap. ISO 15016 verification can, under conditions, strengthen reliability and audit value. Consistent MRV data can underpin compliance, cost reduction and emission reduction legally.

Detailed: When multiple measures are applied simultaneously to reduce carbon dioxide (CO2) emissions, it is crucial to avoid double counting. A marginal approach is used for this. This means that measures are ranked by their cost per avoided ton of CO2 and that their effect is calculated each time relative to an already adjusted baseline. This prevents, for example, a suction sail and an energy-saving device (ESD) from claiming the same reduction. Examples of such ESDs are Propeller Boss Cap Fins (PBCF), small fins behind the propeller cap that reduce vortices, a Pre-Swirl Stator (PSS), fixed fins ahead of the propeller that better align incoming water with the propeller’s direction of rotation, and an air lubrication system (ALS), which applies a layer of air under the hull to reduce resistance.

The most transparent method to make this clear is an annual waterfall analysis, a stacked display of effects in sequence. First a reference is established, for example fuel consumption without measures. Next, the additional effect per measure is shown, always calculated on the basis of emissions already reduced by the preceding measure. This creates an overview that makes it clear which part of the saving is truly attributable to which individual measure.

Assumptions in these analyses must align consistently with measured performance and are preferably verified according to ISO 15016, the international standard for measuring and correcting speed and power data, or an equivalent protocol accepted by classification societies. The results must also be supported by operational data from practice. Internal steering, comprising financial reporting, compliance with regulation and operational monitoring, must also be based on the same dataset. Only then can investors, auditors and supervisors fully rely on the calculated effects.

In practice, wind-assisted systems often belong to the most cost-efficient measures per avoided ton of CO2. Even so, a project-specific analysis remains necessary to determine the right order and mix of measures. This creates a fleet strategy that is financially efficient and demonstrably complies with international regulation.

Safety and Operational Integration

Which Class Requirements Apply to Foundation, Loads and Safety?

Core: Class requirements can mandate assessment of foundation, mast and deck for wind and vessel loads. Strength and fatigue analyses can, under conditions, substantiate structural integrity and compliance. Safety can require lightning protection, emergency stop and lock-down logic and evacuation paths. Approval can proceed via a phased process with design, class review and quay and onboard tests.

Detailed: Classification societies impose strict requirements on the substantiation of wind-assisted installations. It starts on the structural side. The design documentation must demonstrate that mast, foundation and deck can withstand the relevant wind loads and vessel motions. This includes strength calculations and a fatigue analysis that together underpin the structural service life of the installation. Requirements also apply to secondary but crucial aspects, such as lightning protection, fire integrity and keeping escape routes clear. This creates a broad assessment that covers both the structure and operational safety.

In practice, this means that shipping companies must calculate overturning moments and horizontal and vertical forces per sea state and loading condition. The mast and foundation are generally protected by a certified grounding and bonding concept that provides protection against lightning strikes and electrostatic discharge. For operational safety, an emergency stop logic can be required that places the system in a predefined safe position, fail-safe. Lock-down mechanisms, with which the installation can be secured under extreme conditions, also form part of this safety architecture in many cases.

Finally, evacuation paths and emergency exits may not be obstructed. This must be demonstrably substantiated in the safety file, generally with integration of layout drawings, evacuation calculations and fire scenarios. The certification trajectory proceeds in phases, from a preliminary assessment during the concept phase, through detailed engineering and class review, to final approval. The process concludes with quay and onboard tests, in which the calculated performance and safety provisions can be validated in practice. This creates a transparent trajectory from design to operation, which provides certainty for both shipping company and supervisor.

Stability, Wind Loading and Sight Lines: Where Are the Limits?

Core: Stability and sight lines can be limited by higher wind loading and obstruction with suction sails. The IS Code can set limits via wind heeling moment. SOLAS V/22 can require clear view of 500 meters or two ship lengths. Mitigation may be possible with tilting masts, camera systems or alternative conning positions. Class acceptance and flag state verification can be decisive for compliance and operational safety.

Detailed: A suction sail captures additional wind and this can affect two core aspects, the stability of the vessel and the view from the bridge. Strict international rules apply to both subjects. Stability is assessed according to the International Code on Intact Stability (IS Code). The emphasis is on the wind heeling moment, the overturning moment that can arise due to wind loading at different loading conditions and trim situations. For sight lines, Chapter V, Regulation 22 of the International Convention for the Safety of Life at Sea (SOLAS) applies. This provision prescribes that from the bridge there must be a clear view of the sea up to 500 meters or two ship lengths, with only limited blind spots.

In addition to these formal requirements, practical limitations also play a role. Bridges or quays with limited air draft can restrict deployment. In such cases, the suction sail must be able to be lowered or tilted, a provision that is recorded in the passage plan in advance. If the sail can obstruct the view from the bridge, technical aids can provide a solution. Examples are camera systems or alternative conning positions, which ensure that the crew can be expected to retain full visibility of the surroundings.

All calculations and choices made are included in the class file and recorded in the onboard operational procedures. This provides evidence that both the structure and use are in line with international standards. This provides assurance that the application of a suction sail in practice not only delivers fuel and emission reduction, but also remains safe within the requirements for stability and sight.

Icing and Anti-Icing: Which Measures Are Required?

Core: Icing can cause additional mass and wind loading with wind-assisted propulsion and requires a formal risk analysis. Classification societies can mandate detection, de-icing and anti-icing systems depending on sea area and route. Technical measures can include heated or coated leading edges and drainage channels. Operational stop criteria and manual procedures can underpin compliance, safety and auditability.

Detailed: On cold routes, ice accretion is a real risk that must be explicitly substantiated by classification societies. A formal risk analysis therefore generally forms part of both the design and the operational framework. This analysis can include timely detection of ice formation, as well as procedures for de-icing, removal of existing ice accretion, and anti-icing, prevention of new ice accretion, clear stop criteria and safe access for inspection and maintenance. The aim is to limit additional mass, increased wind loading and the risk of falling ice, so that the safety of vessel and crew can demonstrably remain assured.

Technically, this is often translated into heated or coated leading edges of the profile, effective drainage channels that discharge meltwater in a controlled manner and maintenance intervals tailored to climate, seawater temperature and sailing speed. Operationally, it can be recorded under which conditions the system automatically throttles back or is switched off, and when the crew secures it manually in a safe position. This prevents the suction sail from remaining active under conditions in which this would be unsafe.

All arrangements are recorded in the Operations Manual of the vessel. This manual includes, among other things, stop criteria, instructions for periodic inspections, logging procedures and specific training for the crew. This creates a closed basis for audits, evaluations and approval by classification societies. In this way, it can be convincingly demonstrated that the risks of ice formation can be effectively controlled both technically and operationally.

Electromagnetic Compatibility (EMC) and Noise: How Do You Prevent Interference?

Core: EMC and noise requirements for suction sails can be assessed according to IEC standards and class guidelines. Interference can be limited with shielded cables, segregated routing, filters and reliable grounding. Testing and measurements can be mandatory to secure safety and compliance. Results can be recorded in the class file and ISM system for audit and verification.

Detailed: Electromagnetic compatibility (EMC) and noise levels are of great importance for both safety and comfort onboard. EMC describes the extent to which electrical and electronic systems can function without disturbing each other. Wind-assisted propulsion systems such as suction sails also fall under these requirements and must comply with the standards of the International Electrotechnical Commission (IEC). For installations in and around the bridge, additional criteria apply, both for electromagnetic emission, the extent to which equipment can emit signals, and for immunity, the extent to which equipment can be resistant to external disturbances.

A robust design can prevent interference by shielding cables, routing power and signal cables separately, applying proper grounding and installing filters that suppress unwanted signals. After installation, a verification trajectory generally follows in which noise levels and vibrations are measured during factory tests, acceptance and commissioning tests and sea trials. The results are recorded in the class file and included in the International Safety Management (ISM) system. This creates a demonstrable link between technical assurance and the safety culture onboard.

Should interference occur later, the cause in practice is often traceable to cable routing, inadequate grounding or insufficient filtering. Thanks to systematic documentation and the audit trail, such a problem can generally be resolved quickly and purposefully, without structurally endangering the reliability or availability of the installation.

Port Operations, Pilotage and Emergency Procedures: What Must Be in the Manual?

Core: The Operations Manual can mandate port mode, emergency stop, fail-safe and interlocks for suction sails. During pilotage, bunkering or high winds, the system can switch automatically to feather or lock-down position. ISM checklists and crew drills can strengthen assurance and compliance. Class and flag state acceptance can be decisive for audit and safety.

Detailed: A suction sail requires a clear operational framework for use during port operations and in situations in which safety has priority. Because the exact implementation can differ per supplier, classification societies emphasize a number of basic functions that must in any case be present, such as a port mode, emergency stop, fail-safe and interlocks.

The Operations Manual of the vessel therefore in most cases contains a special port mode. In this mode, use of the system can be limited or adapted during port maneuvers. Clear procedures can also be included for pilotage, bunkering and sailing in heavy weather. For emergencies, an emergency stop (e-stop) is generally applied that immediately places the system in a safe position at the push of a button. If sensor data is unexpectedly lost, the system switches automatically to a fail-safe mode, a predefined safe position of the sail.

Concretely, this often means that during tug or pilot assistance the suction sail can automatically go into one of two positions. In the feather position, the profile is rotated so that aerodynamic drag is minimized, while the lock-down position means the system is mechanically secured. Interlocks are also generally built in that prevent the system from being activated inadvertently during, for example, bunkering or crane operations. Threshold values can also be preset for factors such as wind direction, wind speed and wave height. As soon as these values are exceeded, the system switches off automatically.

These arrangements are translated into drill scenarios and checklists that form part of the International Safety Management (ISM) system. The crew is trained in these and execution is regularly tested. Incidents and near misses are recorded and analyzed systematically. On that basis, procedures can be continuously improved. This not only meets formal safety requirements, but also creates a learning process that can structurally strengthen the reliability and safety of the suction sail in practice.

Which Port Aspects Are Relevant for Deploying Suction Sails?

Core: Ports can require that suction sails do not hinder bunkering, cranes and cargo. Air draft limitations can make tilting masts necessary for operational safety. Procedures can be coordinated in advance with port authorities and recorded in the Operations Manual. Conditions can be linked to CEF financing and auditable compliance obligations.

Detailed: Deployment of suction sails is not limited to seagoing operation, but also extends to port operations. Precisely there, strict framework conditions apply that determine whether the system can be used safely, efficiently and practically. As a basic requirement, port authorities stipulate that installations must not obstruct essential activities such as bunkering, use of cranes and lashing of cargo. This means that safety zones on deck are often defined in which certain activities may or may not take place. By recording these zones formally in the vessel documentation and having them approved by both the port authorities and the classification society, a clear operational demarcation is created that helps prevent risks and can withstand audits.

A second aspect concerns air draft. At bridges, cranes or quays with limited clearance height, a fixed suction sail can be an obstacle. In such situations, tilting or lowering masts offer a solution. These structures make it possible to temporarily take the installation out of service without endangering safety or logistical flow. This enables the vessel to continue to call at ports without problems, while retaining the benefits of wind assistance during the voyage. In this way, the balance between operational flexibility and technical performance can remain assured.

Coordination with port authorities also plays a crucial role. Procedures for bunkering, pilotage and crane operations must be aligned with the presence of suction sails. This requires a clear Operations Manual in which the port mode is described, including the positions the system is in during maneuvers and port operations. When these arrangements are recorded transparently in advance, interaction with port personnel generally proceeds smoothly and predictably. This can prevent unexpected delays or safety conflicts.

At European level, there is also a direct link with financing. Programs such as the Connecting Europe Facility (CEF) explicitly include port logistics in their project definitions. This means that investments in fleet retrofits are often linked to parallel improvements in port infrastructure. In this way, shore side and vessel side reinforce each other. The technical modification onboard aligns seamlessly with the logistical facilities in the port. This creates an integrated approach in which both safety and efficiency can remain assured and in which the benefits of wind assistance can be maximized without compromising operational continuity.

This makes it clear that port aspects are not merely practical boundary conditions, but form a structural part of the business case. By bringing together safety zones, air draft limitations, operational coordination and financing frameworks, a closed whole emerges. In this way, the deployment of suction sails remains legally, technically and operationally robust not only during the voyage, but also in port.

Subsidies and Financing

Which Subsidies and Research Programs Are Available for Wind-Assisted Propulsion?

Core: Subsidies for wind-assisted propulsion can be available via the EU Innovation Fund for demonstration projects with demonstrable emission reduction. Horizon Europe and ZEWT can support research into verification and validation methods. One consistent dataset can, under conditions, underpin subsidies, EU ETS and FuelEU Maritime compliance simultaneously. Transparency and auditable assurance can be essential for approval and financing.

Detailed: At European level, there is a broad palette of instruments specifically designed to support the introduction and scaling of wind-assisted propulsion. The principal financing mechanism is the Innovation Fund. This fund can support large-scale demonstration projects that demonstrably reduce emissions and whose financial feasibility is convincingly substantiated. It requires not only technical performance to be clear, but also the cost structure and scalability. Public support is therefore provided only to projects that offer a realistic perspective to make an impact at fleet level.

In parallel, Horizon Europe plays a crucial role. Within this research program, the Zero Emission Waterborne Transport (ZEWT) partnership focuses on fundamental and applied questions around vessel emissions. Think of research into validation methods, measurement protocols and verification techniques that can later be used in audits and certification. This creates a bridge between scientific research and practical application in the fleet. The results of this research feed directly into the assessment criteria of subsidy programs and the compliance frameworks of supervisors.

This coupling offers an important operational advantage. The same dataset that underpins the performance of a suction sail, for example shaft power, fuel flow and wind conditions, can be used simultaneously in multiple trajectories. In this way, one consistent set of measurements serves as evidence for technical validation, as substantiation for financing applications and as a basis for external audits. This can reduce administrative burden and strengthen the reliability of reporting.

By using the Innovation Fund and Horizon Europe in conjunction, an integrated trajectory emerges from research to fleet rollout. Research provides robust methodologies, subsidies lower the investment threshold and the joint emphasis on measurability ensures that all results remain transparent and reproducible. In this way, Europe not only accelerates the introduction of wind-assisted propulsion, but also ensures that the technology can be rolled out in a technically solid, financially feasible and policy-anchored manner.

How Do I Finance Wind-Assisted Propulsion via Banks and European Institutions?

Core: Financing of wind-assisted propulsion can be arranged via EIB loans with guarantees, CEF subsidies and commercial bank financing. This mix can reduce risks and shorten payback time. EU ETS and FuelEU Maritime savings can strengthen cash flows and support compliance. Auditable assurance can be a condition for approval and sustainable financing structures.

Detailed: For financing wind-assisted propulsion, in addition to commercial banks, European institutions are of great importance. The European Investment Bank (EIB) plays a central role. Through green guarantees and long-term loans, the EIB can provide capital under conditions that are more favorable than in the private market. These loans are often combined with commercial bank financing, creating a hybrid structure in which public certainty stimulates private participation. This increases access to capital and can reduce risks for all parties involved.

A second important pillar is the Connecting Europe Facility (CEF). This program primarily targets financing maritime infrastructure, such as charging infrastructure or bunkering facilities. In practice, CEF is increasingly linked to fleet retrofits within broader decarbonization programs. As a result, investments in suction sails can not only benefit directly from infrastructure subsidies, but can also be included indirectly in broader project structures in which ports and shipping companies cooperate.

This combination can deliver clear financial advantages. Because the capital burden decreases and the payback period is shortened, the business case for wind-assisted propulsion can become more robust. At the same time, the operational benefits of the European Emissions Trading System (EU ETS) and FuelEU Maritime provide a more stable cash flow. Savings achieved by a suction sail directly reduce the ETS payment and can improve FuelEU Maritime compliance. This creates a demonstrable link between technology, compliance and financing.

By combining EIB loans, CEF subsidies and commercial bank financing strategically, a multi-year investment plan can be built that is predictable and scalable. The result is that shipping companies can decarbonize their fleet step by step, while financial risks remain limited and operational benefits are immediately visible. This makes wind-assisted propulsion not only a technical innovation, but also a financially viable choice within stricter European regulation.

Which Fiscal Schemes for Wind-Assisted Propulsion Apply in the Netherlands?